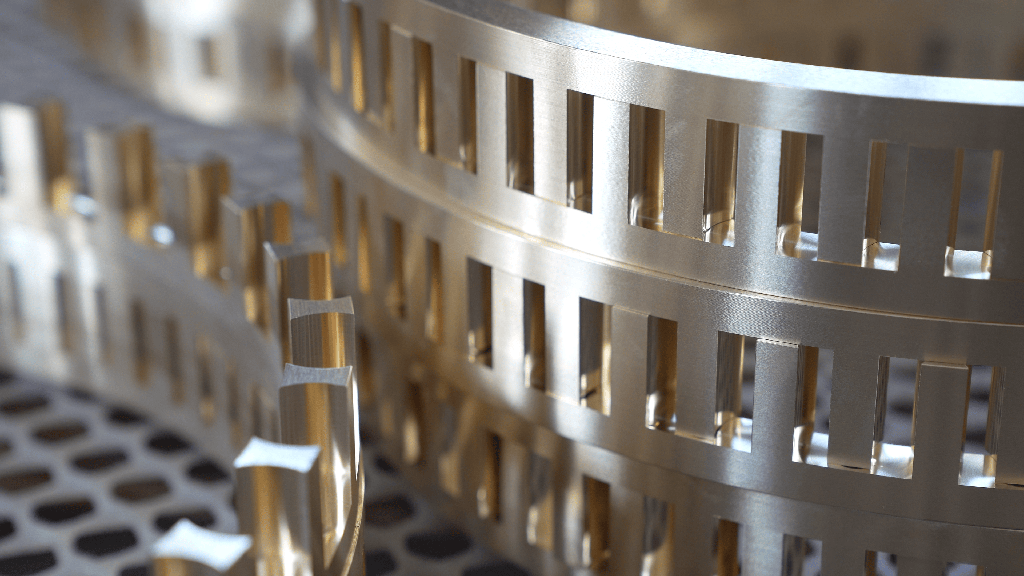

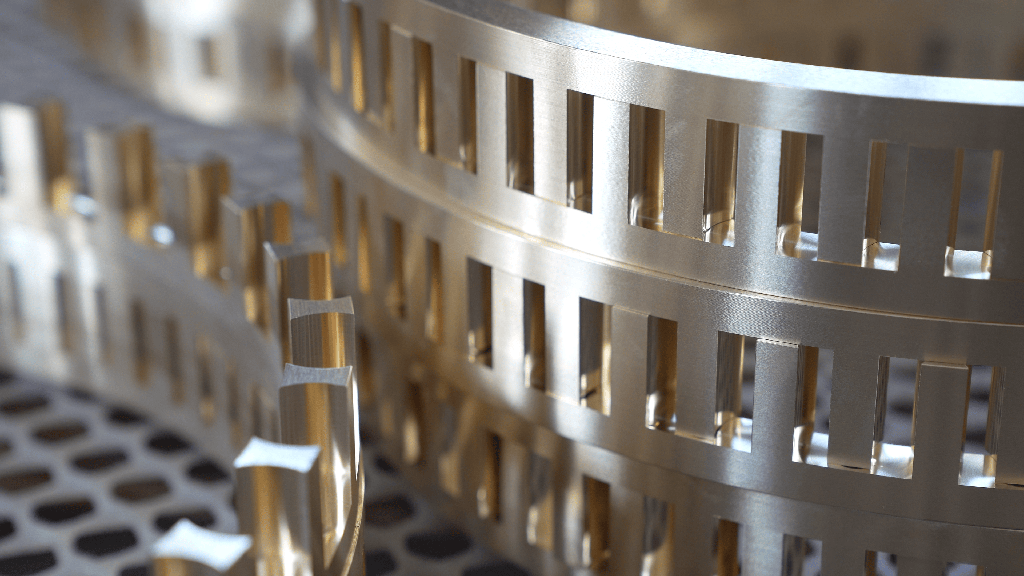

Bearing

cages play the roles of positioning and separating rolling elements, guiding

their movement, and optimizing internal lubrication of bearings. Their

precision, strength, wear resistance, and material stability directly affect

the bearing's rotational accuracy, operating noise, service life, and

reliability under heavy-load conditions.

ESG

Bearings is committed to developing and manufacturing high-end rolling mill

bearings of superior quality that can replace those from international well-known

brands. In 2024, we began recommending manganese brass cages to long-term

customers, who have all expressed recognition and support for this material

after usage. Now manganese brass cages have become the standard configuration

for ESG Bearings.

The

following is a comparative analysis of the composition

and mechanical properties between manganese brass cages and

common brass cages:

1. Main

Chemical Composition

Manganese

Brass (ZCuZn38Mn2Pb2)

|

Element

|

Cu

|

Pb

|

Mn

|

Zn

|

|

Content

Range

|

57-60

|

1.5-2.5

|

1.5-2.5

|

balance

|

Common Brass (ZCuZn40Pb2)

|

Element

|

Cu

|

Pb

|

Mn

|

Zn

|

|

Content

Range

|

58-63

|

0.5-2.5

|

/

|

balance

|

2. Mechanical

Properties

Manganese Brass (ZCuZn38Mn2Pb2)

|

Tensile

Strength ≥ 380Mpa

|

Elongation ≥ 22%

|

Hardness ≥ 100HB

|

Common Brass (ZCuZn40Pb2)

|

Tensile

Strength ≥ 280Mpa

|

Elongation ≥

20%

|

Hardness ≥ 90HB

|

3. Analysis

Key Difference

The

addition of manganese provides solid solution treatment and grain refinement

effects in manganese brass. Compared to common brass (ZCuZn40Pb2), its tensile

strength is increased by approximately 25-30%, significantly improving the

strength, hardness, and wear resistance of the manganese brass cage.

Higher Strength and Hardness

High

strength and hardness are among the most critical properties for bearing cages.

Under complex operating conditions such as high-speed rotation, centrifugal

forces, impacts from rolling elements, and friction, manganese brass cage will

maintain structural stability, avoid plastic deformation or excessive wear, and

reliably withstand dynamic loads to extend service life.

4. Conclusion

Manganese Brass (ZCuZn38Mn2Pb2), with

high strength and excellent wear resistance, this material is suitable for

harsh operating conditions such as high speed, heavy load, impact, and vibration.

It is a high-performance material particularly well-suited for applications

requiring high reliability.

Common Brass (ZCuZn40Pb2), is

suitable for general-purpose applications.

The

advantages of ESG Bearings' cages lie not only in the material selection, but

also in precision machining, manufacturing and tight dimensional control. These

factors deliver a comprehensive improvement in cage performance, further

reducing friction and heat generation during bearing operation, thereby

extending the service life of the bearings. Manganese brass cages are applied

to the work roll bearings (like four row cylindrical roller bearings) of steel

mill rolling mills. They can operate stably for a long time under high-speed,

heavy-load and shock working conditions, significantly reducing bearing

maintenance frequency and downtime risks, and helping steel mills achieve

efficient production.

+86-13790878972

+86-13790878972 overseas@esgbearing.com

overseas@esgbearing.com +86-13790878972

+86-13790878972